Ultra-thin silicon wafer photovoltaic panel price list

Flexible solar cells based on foldable silicon wafers with blunted

Silicon is the most abundant semiconducting element in Earth''s crust; it is made into wafers to manufacture approximately 95% of the solar cells in the current photovoltaic

China M6 Mono Silicon Wafer,M6 IBC Solar Cell,HJT

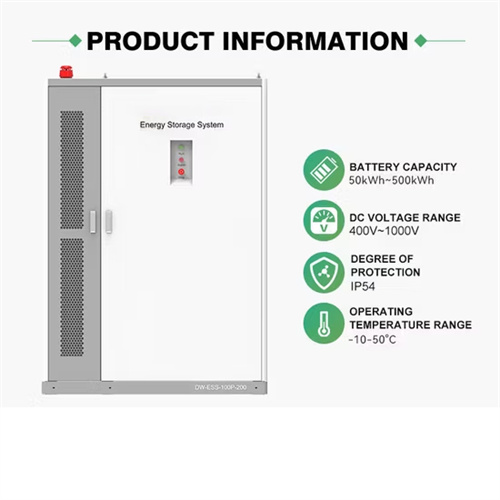

A leading mono silicon wafer,IBC solar cell,HJT PV module supplier. GreenTrend has been at the forefront of developing efficient and eco-friendly solar solutions. Commercial 100kW 200kW 500kW Hybrid Storage Solar System Lithium

Oxford, UK, reveals ''breakthrough'' ultra-thin

PV Tech has been running PV ModuleTech Conferences since 2017. PV ModuleTech USA, on 17-18 June 2025, will be our fourth PV ModulelTech conference dedicated to the U.S. utility scale solar sector.

A critical review on the fracture of ultra-thin photovoltaics silicon

The main research method is to carry out 3 PB test on the whole PV silicon wafer (156 mm × 156 mm) in two directions of vertical to and parallel to saw marks, and the

Thin Silicon Wafers in Solar Cells

This means that only ¼ of the current number of wafers used in a solar panel will be necessary. Thin Wafers Allow an Increase in Manufacturing Capacity of Solar Cells. Now that more wafers can be produced from a single silicon crystal

Electronic Characteristics of Ultra‐Thin Passivation Layers for Silicon

1 Introduction. Crystalline silicon (c-Si) is the backbone of today''s photovoltaics industry, accounting for over 95% of current commercial production. [] Passivated emitter and rear cell

Ultra thin silicon wafer slicing using wire-EDM for solar cell

The optimum wafer thickness to get the highest power conversion in PV cell is 80 μm with diffusion length of 200 μm, and thickness 120 μm for the diffusion length of 400 μm

What Is a Silicon Wafer for Solar Cells?

P-type (positive) and N-type (negative) wafers are manufactured and combined in a solar cell to convert sunlight into electricity using the photovoltaic effect. Thin-film solar panels do not use wafers but are highly

Ultra-Thin Silicon Wafers 2 micron thin

New Process to Fabricate Ultra-Thin Silicon Wafers. Thin Silicon Increases Solar Panel Efficiency. Climate change (formally referred to as global warming) is the greatest problem earth faces today. (Pseudo-Square), PV, Coin-roll

Solar Silicon Wafers as-cut wafers high-quality-low-price

Silicon Wafer Improve Light Absorption. Only limited work has been done with Silicon wafer based solar cells using Ag or Al nanoparticles because of the fact that the thickness of Si-wafer cells

Related Contents

- Dehong Solar Photovoltaic Panel Price List

- Price list for photovoltaic panel double column installation

- Photovoltaic panel factory price list picture collection download

- House photovoltaic panel price list

- Silicon factory photovoltaic panel price

- Floor photovoltaic panel price list

- Solar photovoltaic panel silicon wafer repair

- Price list for photovoltaic panel removal

- Silicon wafer semiconductor photovoltaic panel manufacturers

- The latest price list of photovoltaic panel brackets

- Photovoltaic panel price list for home use

- Price list for low voltage photovoltaic panel installation